Our Products

Suspended Sandblasting Machine

Tunnel Type Sheet Profile Shot Blasting Machine

• Tunnel Type Sheet-Profile Shot Blasting Machines

It is used for surface cleaning of parts such as sheet metal, steel construction, IPE, HEA, NPU and NPI, profile, flat bar and angle iron.

As you request, projects of all sizes of machines are made.

Cabinet Type Drum Sandblasting

• Cabin type drum sandblasting machine puts small parts inside the drum.

They are machines that make sandblasting automatically.

• Cabin type drum blasting machine has double nozzles and one of the nozzles is attached to the drum.

It has a feature that can be adjusted permanently according to the other nozzle, and it has the feature of manually sandblasting.

Die Blasting Machine

• Die blasting machine is pressurized blasting and it is machines capable of mass blasting with all kinds of sand throwing capacity.

• They are special production machines used for surface cleaning of epoxy paint, rust, molds in pressure sandblasting machines.

Automatic Rotary Table Pressure Shot Blasting Machine

• Automatic rotary table, double nozzle, serial sandblasting capacity. It is a specially produced pressurized sandblasting machine, a special type servo motor is used for serial works, which can be adjusted according to the piece length. Thus, it has the capacity to sandblast 650 to 900 pieces per day.

Continuous Suspended Sandblasting Machine

• Continuous suspended sandblasting machines are specially manufactured machines with double-sided inlet as serial sandblasting machines.

• The feature in continuous sandblasting machines is that the material to be sanded is loaded on one side and it comes out as sandblasted on the other.

Sandblasting Room

• ALP-KUM Sandblasting Rooms are the most ideal solutions for sandblasting large parts.

• System sandblasting room (cabin-room), conveyor, spiral, elevator, separator, filter, dust trap system, piping system, control panel, lighting, personnel door, observation window, service ladder and platforms, grill, rails, walkway, It consists of material inlet and outlet door, movable car, conveyor and portable pressure sandblasting machine.

Drum Blasting Machine

• It is used in preparation before paint and rubber coating by making surface roughening of the sheet metal parts that came out of the press, descaling of hot forged parts, revision of old parts, cleaning of aluminum injection molding and brass forging parts, and tensioning of compression springs.

• It is available in 100 kg, 250 kg, 350 kg, 600 kg, 800 kg in our product range, which varies according to the work capacity.

Sandblasting Machines Spare Parts

• All kinds of spare parts and consumables required for sandblasting machines offer you professional service and high quality together...

Vacuum Sandblasting Machine

• Vacuum Sandblasting Machines are simple-to-use machines designed in a three-dimensional computer environment and designed to respond to special requests.

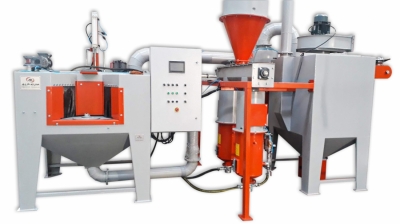

Pressure Cabinet Shot Blasting Machine

• Cabin Type Pressure Sandblasting Machines are jet-pulse system, automatic time-adjusted, self-cleaning, high-suction, feedback-feeding machines.

Marble Sandblasting Machine

• The machine is designed and manufactured according to the size, type and daily number of the parts to be sanded. Optionally, a dryer can be added to dry the wet surfaces before sandblasting.

Portable Sandblasting Machine

• Portable Pressure Sandblasting Machines are a design offered complete with a boiler (tank), compressed air filter, sandblasting valve, breathing filter, sandblasting and air hose, compressor hose, mask, nozzle and nozzle apparatus. It works by means of compressed air. Air is connected to the machine and sandblasting is applied in this way. A screw compressor with a flow rate of 5-6 m³/min is suitable.